Retrofit project in the ventilation system of a newspaper

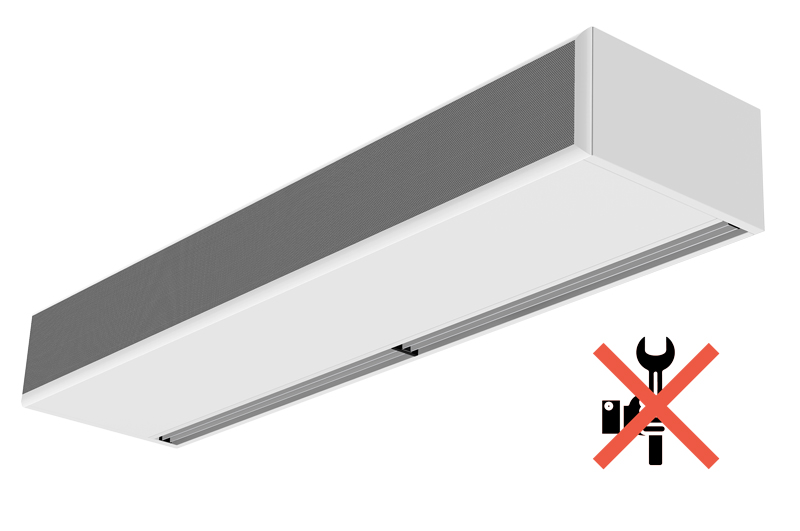

Replacing centrifugal belt-driven fans with EC FanGrids (fan walls distributed in parallel) reduces energetic consumption, provides the air handling unit with a constant flow rate proportional to the number of fans used. Our partners at Rosenberg are specialists in retrofit projects.

Projects in which ventilation systems are renewed are an effective method of improving efficiency, reducing energy consumption and, in the medium term, saving money. EC fans give the unit a perfect balance between electronics, motor and fan blades.

Retrofit project

At a major German newspaper printing house with a large circulation, there was a need to replace a belt-driven forward blade centrifuge fan with a conventional motor that had been in operation for more than 30 years. After all those years of operation with 40,000 m³/h / 600 Pa, the aim of the retrofit project was not only to focus on the energy saving objective, but also to ensure a guaranteed operation.

To avoid stoppages in the operation of the ventilation system, the EC Fan Grid is the ideal system. If one of the EC fans in the grill stops, the rest of the fans, which have automatic regulation controls, adapt the power required to continue providing the same airflow to the unit.

In this project carried out by our partners at Rosenberg, energy savings of 42% have been achieved thanks to the new low-efficiency EC motors and the optimisation of the air volume for the actual demand.