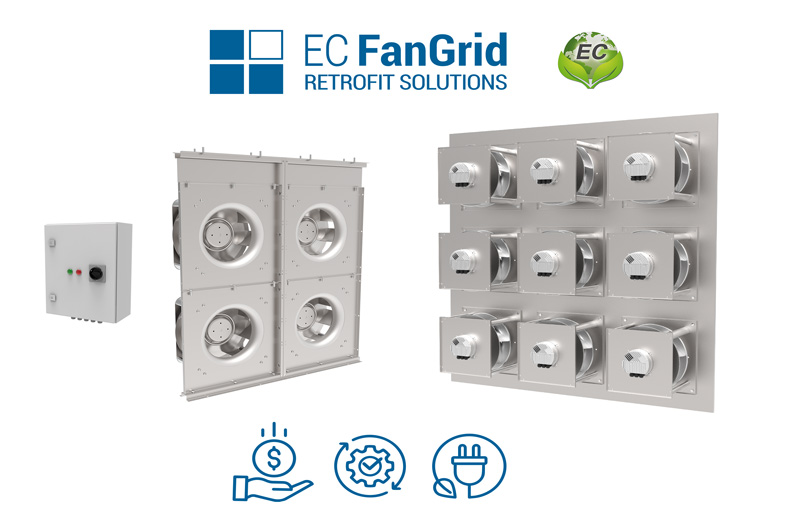

Retrofit projects with EC Fan Grid save energy

Given the importance of environmental protection and the need to save energy, one of the many demands in ventilation projects is the replacement of the large belt-driven fans. The air handling unit is completed with new EC Fan Grid fans, which form a grid of smaller fans, but with the same flow rate.

The main advantage of having EC Fan Grid in an air handling unit, apart from the well-known energy savings, is the self-regulation in case of failure, the system continues to operate, and the ease of maintenance of the unit.

Our partner Rosenberg has carried out an energy saving project once again, which is a key part of the group's green policy. They have executed the retrofit project of an old belt-driven fan in an air handling unit.

In this installation, the new EC Fan Grid fans move an airflow of 50,000 m3 per hour. This EC FanGrid is the central connection point that supplies the air to the other fans.

The airflow from the EC FanGrid fans is much more efficient and reaches the other components (filters, heat exchangers...) of the AHU in a more uniform way, which helps to increase the longevity of the components' lifetime.

As a result, the baffle plate could be eliminated, which helps to reduce pressure losses.

With this project completed in just three working days, more than 44% of energy will be saved, or in climatic terms: approximately 10 tonnes of CO2 per year will be reduced.