ECFanGrid retrofit project for a factory in a food product company

In a food products company, specifically a packaging plant for ready-to-drink products, our partners from Rosenberg France and their trusted installation company, obtained a retrofit project for the renovation of the AHU. They opted for an ECFanGrid with high-performance, low-consumption fans.

In this installation, they required an output of approximately 25,000 m3 of air per hour, working at 83% speed and with the possibility of increasing the flow rate by 17%, up to more than 30,000 cubic metres per hour if necessary.

FLEXIBLE CONFIGURATION

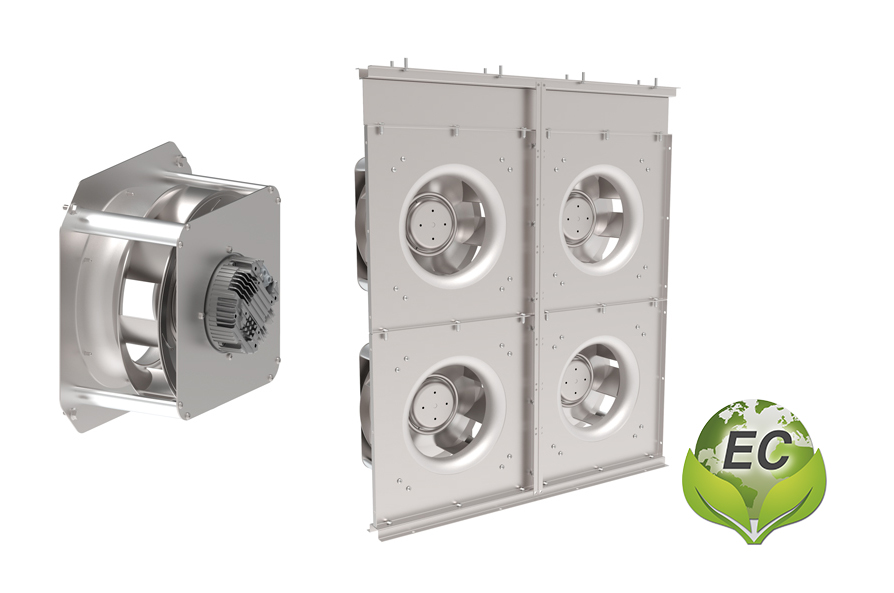

This project was carried out with five EC fans with free impeller of 400 mm diameter, with turbine made of black polyamide and polypropylene finished with ultraviolet reinforced with fibreglass. They were configured in a 4x2 design.

With this installation, a reduction in energy consumption of more than 59% will be achieved, while maintaining the same air renewal performance. Now, it is a redundant design, which is the most remarkable feature of the ECFanGrid. If one fan fails, the other four fans adapt their capacity to achieve the 25,000 m3/h for which the air handling unit is designed.

Equipment with added redundancy improves on older units, because the machine never stops working, ensuring a better environment and safety in an installation that can be considered critical.

PACKAGING AND COMMISSIONING

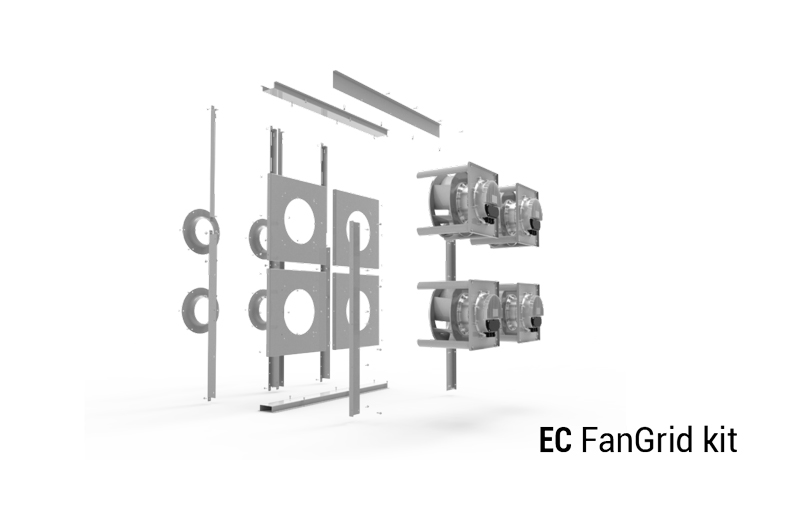

The commissioning is executed in one day. The replacement of the old fan and the assembly of the innovative ECFanGrid is fast thanks to the high adaptability of the equipment to small spaces. Also the assembly kit that Rosenberg France delivered to its installation technicians helped in the work.

The installation team had at their disposal the fans, the reinforcement profiles, the adapter plates, the electrical cabinet, the constant flow and pressure control... in short, all the components to get the unit up and running.

Other news about retrofit projects: